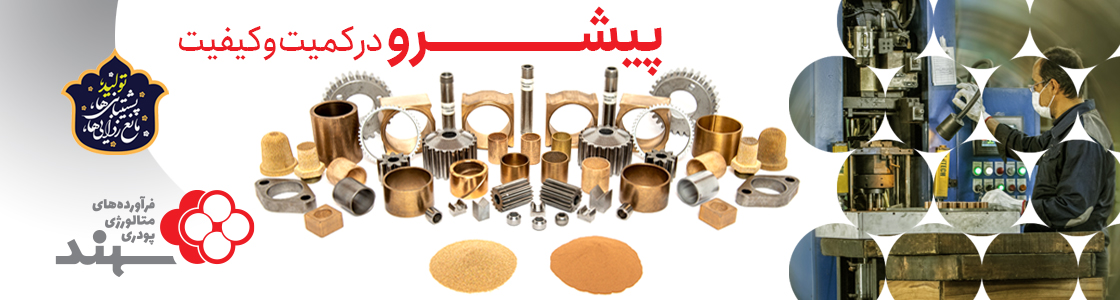

Indigenization of industries of the country

After 40 years of establishment, the company based on its technology and experience as well as indigenized know-how and enjoying skilled and experienced staff which are specialized in production, has succeeded in receiving the certification of ISO 9001:2000 for Quality Management System.

Some of the important achievements of the company are to indigenize the technology for the country’s industries, reduce imports and decrease the forex outflows, countering cruel sanctions on Iranian industries, internalize technology and supply raw materials needed by the country’s industry which are the result of the endeavors of the Sahand Powder Metallurgy Company during recent years.

In addition to exporting its products to reginal countries, the company has met the needs of domestic producers and eliminated the need for Iranian companies to import high-quality raw materials.

Indigenization of industries of the country

Reduce imports and decrease the forex outflows

Countering cruel sanctions on Iranian industries

Indigenizationof technology and supplying raw materials needed by the country's industry

Employing professional, young and efficient labor force

Employing experienced and specialized staff

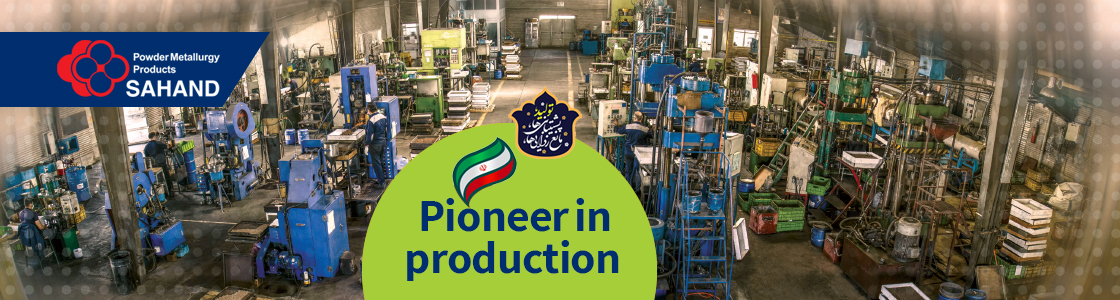

Modern technology and equipment

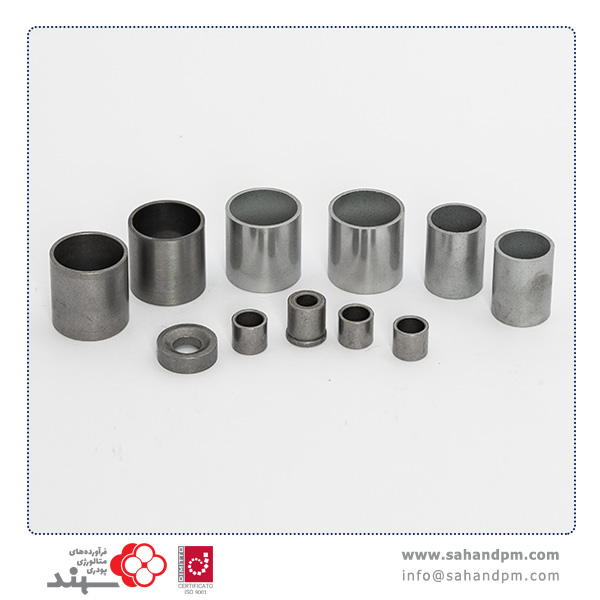

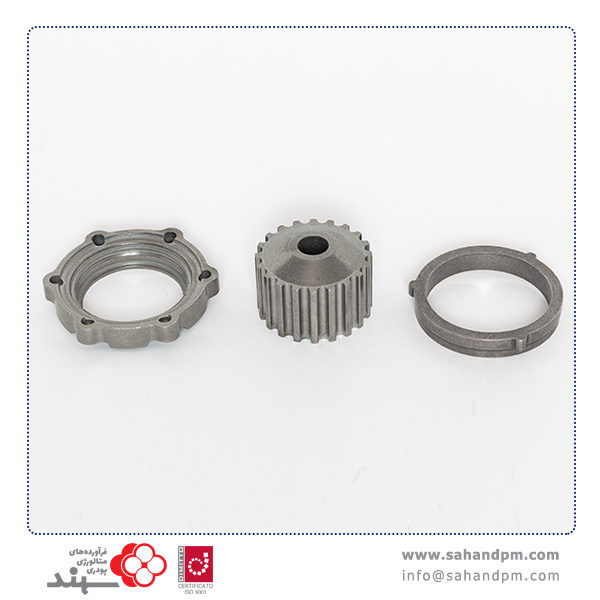

Using modern technology to produce metallurgical parts

Compliance with international standards

Production in agreement withdomestic and international standards

40 years of experience and technology

Four decades of production based on technology, experience and technological knowledge